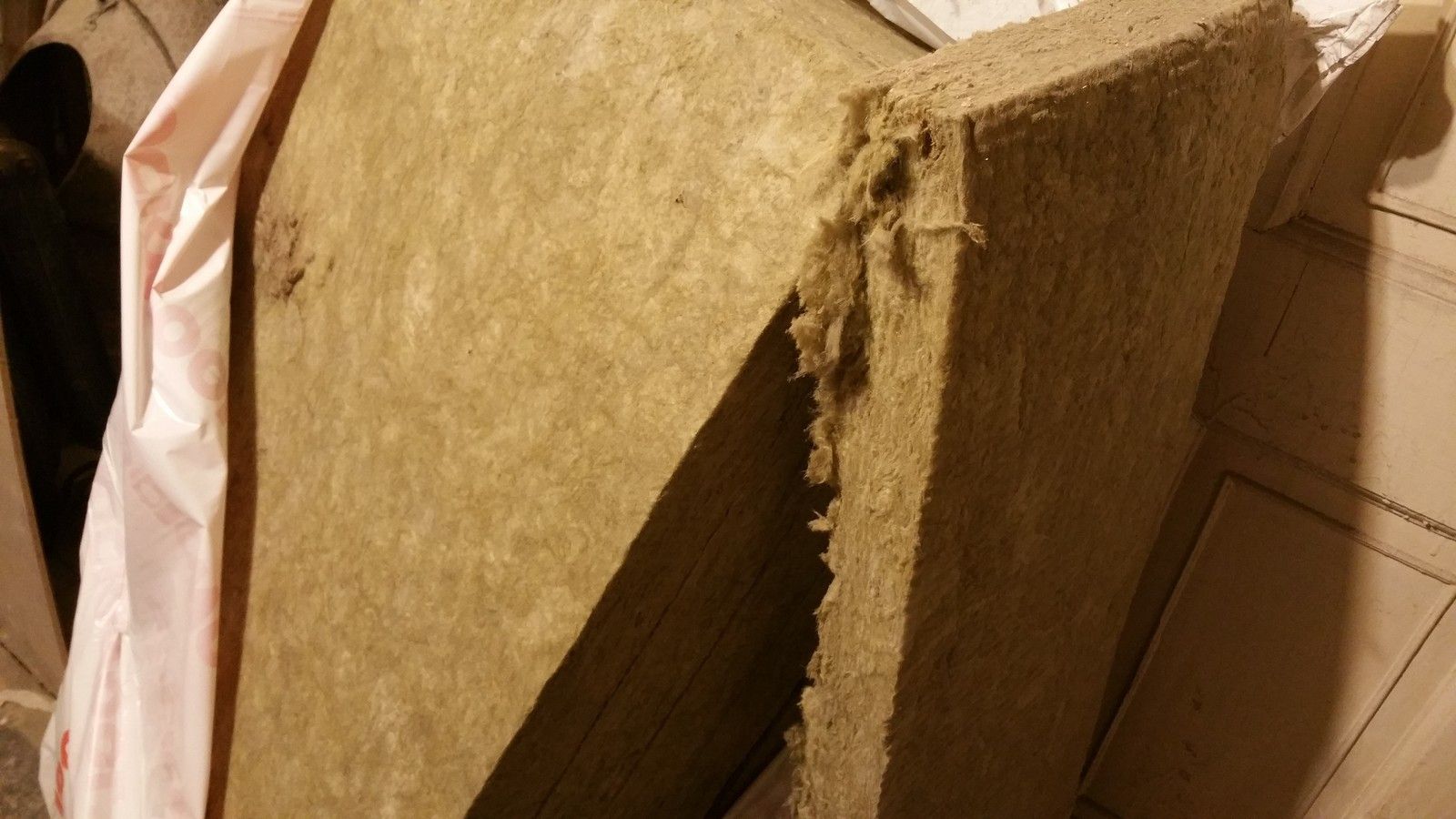

At last the first floor front room (living room) had its ceiling installed. The ceiling was filled with rockwool for sound/heat insulation and then slabbed and plastered:

The bedroom behind received the same treatment, but had to be cross-battened to allow room for the above bathroom pipework and additional rigidity due to the weight of a full bath:

(insert final ceiling pic)

The walls are also drying well and are awaiting a skim coat of lime plaster:

This is the lime skim coat which arrived a few days ago. It's pre-mixed so required minimal preparation:

The third window opening in the return was also finally sorted. This opening formed part of the 1950/1960s extension and had a poorly made window installed, which had replaced a previously installed back door. All the breeze blocks laid above and below the window were taken out and filled in again with salvage red brick. A new arched head was also built above the opening:

(insert finished third window pic)

The re-built heads on the other windows turned out very well:

The ground floor rear room walls have always been a problem, since the moment I bought the house. The lower sections of the walls have a sand/cement mix applied and would have been applied to the internal walls within the last 70 years or so in an effort to "keep out damp" or repair damp/damaged lime plaster. The irony is that applying a cement render/plaster traps moisture in the wall, compounding the problem.

This particular room had a concrete slab floor laid, which pushed moisture from the soil up around the edges of the slab into the wall. The cement render on the walls trapped this moisture in place. Once the concrete floor was removed, the walls slowly started to dry out, but the cement render had to be removed to allow maximum drying and breathability.

This render will be replaced with a breathable hydraulic lime plaster. The upper sections of the walls are still lime plaster, but in terrible, cracked/crumbling condition and also patched with modern gypsum plaster so also needs to be removed:

The room as it stands:

The cement on the walls below the window was particularly difficult to remove. Once this is re-plastered in lime, the wall will have full breathabilty from the inside to the outside, with the new lime render on the external wall:

Removing the sand/cement mix from the walls:

More work on this room soon.